Your Reliable Armored Electrical Cable Manufacturer since 2000

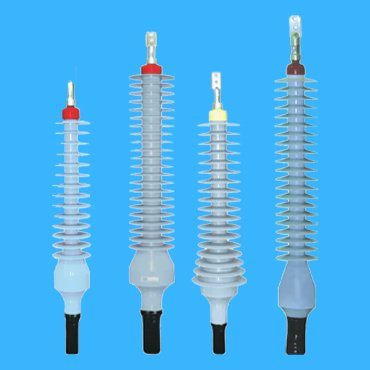

Being a professional manufacturer of Armored Electrical Cable over 20 years, we can provide you a wide range of cables and its accessories, like

- Cable Termination Kit

- Straight Cable Joint

- Cable Link Box

- Pluggable Cable Joint

What is an Armored Electrical Cable

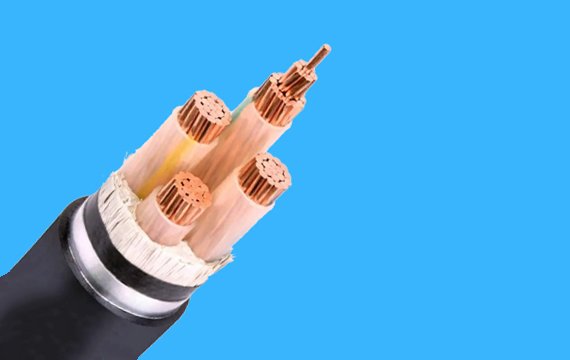

By using smooth or corrugated steel/copper tape, steel or copper wire, it is designed to increase the mechanical strength of cables and improve their corrosion resistance; Cables are designed for areas prone to mechanical damage and erosion; The bending radius of the Armored Electrical Cable should be large, and the armor layer can be grounded to protect the cable, thereby extending its service life.

PowerTel & its associated factory have capacity to provide you a wide variety of Armored Electrical Cable, such as Aluminum alloy cables, cross-linked power cables, PVC insulated power cables, control cables, instrumentation cables, mineral insulated cables, electrical equipment wires and cables, and other types of cables. Special cables can also be customized according to your needs.

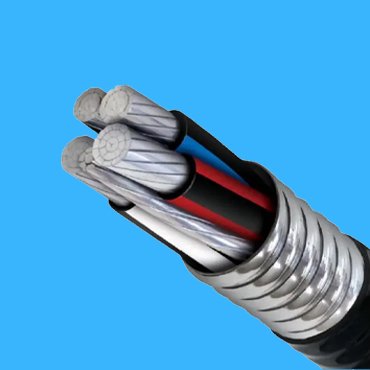

Armored Electrical Cable by different Armoring Materials

Product Feature Box

5S Management Manufacturing Facilities

By implementing 5S Management in our cable manufacturing facilities, it ensures our highest cable quality by identifying and eliminating any potential quality issues. Additionally, 5S Management help us maintain the standard quality of our Armored Electrical Cable by setting and enforcing quality control standards.

Individual Design of your Armored Electrical Cable

Our professional technical support team can design a custom Armored Electrical Cable to meet your unique needs or specifications from your technical datasheet.

Package Supply of Materials

Except Armored Electrical Cable, we are dedicated to provide you cable termination kit, cable gland, staight cable joint, cable link box and elctrical busway & Switchgear, thus to assure a seamless of your electrical system.

Advantages of an Armored Electrical Cable

For an armored electrical cable, it is not only to enhance mechanical protection such as tensile strength and compressive strength, but also to extend its long service life, the most important thing is to improve the anti-interference performance of cables through shielding protection. Commonly used armor materials include steel tape, steel wire, aluminum tape, copper tape or wire, the armoring layer has high permeability and good magnetic shielding effect, which can be used to resist low-frequency interference.

Armored cables can be directly buried and laid without passing through cable duct, and is widely used in practical applications due to its low cost and high quality.

Related Product

What Types of an Armored Electrical Cable

There are electrical cables armored by galvanized steel wire, armored by steel tape, armored by aluminum wire, armored by aluminum tape, armored by copper wires etc.

What components of an armored electrical cable and its technical requirement

- conductor, The surface of the conductor should be smooth and clean, free from oil stains, damage to shielding and insulation burrs, sharp edges, and no protruding or broken single wires. The conductor should be circular and twisted tightly, with a compression coefficient of not less than 0.9. this is for an oxygen free round copper conductor.

- Triple Extrusion, The conductor shielding, insulation, and insulation shielding should adopt a three-layer co extrusion process with fully enclosed chemical cross-linking.

- Conductor shielding layer, The conductor shielding is a extruded cross-linked semi conductive layer, which should be evenly coated on the conductor, with a smooth surface and no obvious twisted wire protrusions, sharp corners, particles, burnt or scratched marks. When peeling off the conductor shield, the semi conductive layer should not be stuck between the conductor strands.

- Insulation layer for an armored electrical cable, The average insulation thickness shall not be less than the specified nominal value, the measured thickness of the thinnest point at any point of insulation shall not be less than 90% of the nominal value, and the eccentricity of insulation on any section shall not be less than 10%.

- Insulation shield layer for an armored electrical cable, it is a extruded cross-linked semi conductive layer, which should be evenly coated on the insulation surface. The surface should be smooth and free from sharp corners, particles, burnt or scratched marks.

- Metal shield layer for an armored electrical cable, it consists of overlapping wrapped soft copper strips, which should be connected by welding and meet the short-circuit temperature requirements. The wrapping should be round and smooth, and the overlap rate should not be less than 15%. And the three core shielding should have good contact.

- The cable core is filled with non hygroscopic materials and should be tightly packed without gaps. The middle of the cable core should also be filled, and the outer shape of the three cores should be rounded after forming the cable.

- Armoring layer, it should be wrapped by steel/aluminum tape or wire and need to be round and smooth.

- Outer sheath for an armored electrical cable, The average thickness of the outer sheath should not be less than the nominal value, and the minimum thickness at any point should not be less than 80% of the nominal value.

- For an armored electrical cable, The non-roundness of the cable should not exceed 15%