A Professional XLPE Insulated Power Cable Manufacturer in China

Being a professional XLPE Insulated power cable manfacturer over 20 years, we are able to prodivde you a wide range of power cable voltage level rated up to 500 kV, also included

- Cable Straight Joint

- Cable Termination Kit

- Pluggable Cable Connector

- Cable Link Box

- Other Cable accessories

What is an XLPE Insulated Power Cable

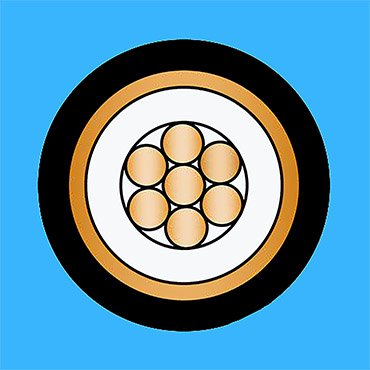

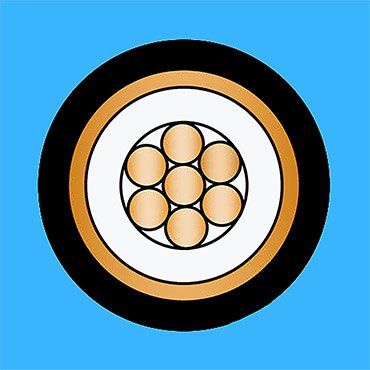

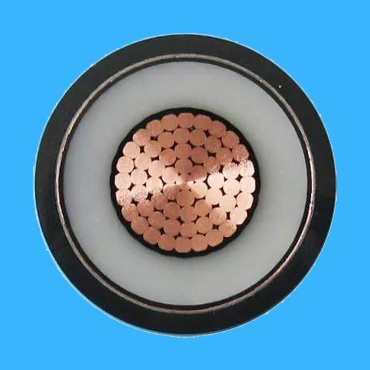

An XLPE Insulated Power Cable means an electrical power cable using XLPE as an insulation material, armored or unarmored and sheathed by PVC or XLPE.

PowerTel & its associated factory have capacities to provide you a wide variety of XLPE insulated power cable, voltage rated from 1 to 500 kV, together with its cable accessories. Cold or Heat shrinkable terminal joint for medium voltage cable and porcelain or composite termination kit for high voltage cables.

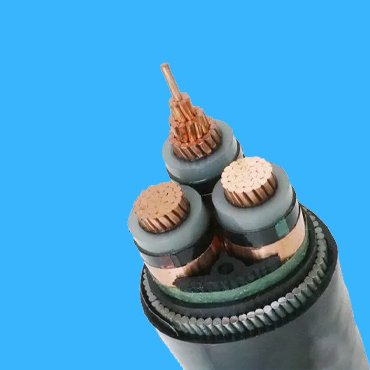

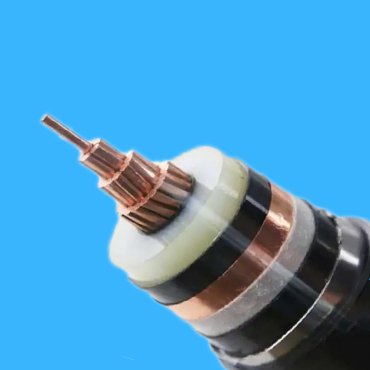

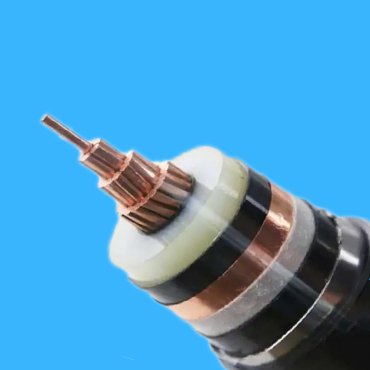

XLPE Insulated Power Cable--High Voltage

Stranded or Segment Al or Cu Consuctor

Conductor Shielded by a Non-metallic or a Semi-conducting Material

Conductor Size from 500 to 5000 kcmil, XLPE Insulated

Conductor range 750 to 6000 kcmil

XLPE Insulated

Triple Extrusion between conductor screen, insulation & insulation screen

XLPE Insulation

Insulation shielded by a Non-metallic or a Semi-conducting material

Metallic layer by Cu wires

Stranded or Segment Al or Cu Conductor

XLPE Insulated

Outer sheathed by HDPE with an Al or Cu tape

Al or Cu Conductor from 1250 to 5000 kcmil

XLPE Insulated

Metallic layer by Cu wires

Stranded, Segment Al or Cu Conductor

Triple Extrusion for conductor screen,insulation & insulation screen

Sheathed by PE with an Al or Cu tape

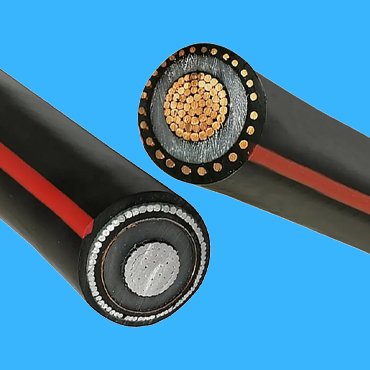

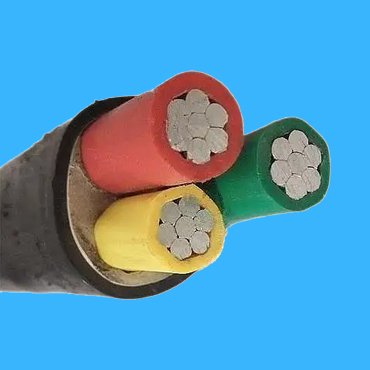

Stranded Cu or Al Conductor to BS 6360

Insulated by XLPE

Conductor shielded by a non-metallic or a semi-conducting material

Referrting to IEC 60840

XLPE Insulation

Insulation shielded by a non-metallic or a semi-conducting material

Water Blocking tape used between Insulation screen & Metallic Cu wires

XLPE Insulated, Sheathed by PE with an Al tape

Solid,Stranded or Segment Conductor

Range from 300 to 2500 mm2

XLPE Insulated

Metallic shielded by Cu wires

XLPE Insulated & Sheathed by PE with an Al tape

Reffering to IEC 62067

XLPE Insulated & Shield by a Semi-conducting material

Triple Extrusion between conductor screen, Insulation & Insulation screen

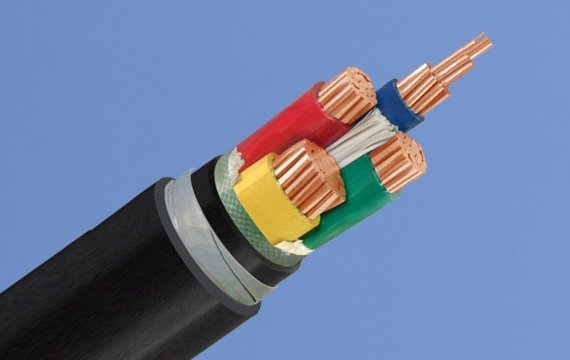

XLPE Insulated Power Cable--Medium Voltage

XLPE Insulated Power Cable--Low Voltage Level

Product Feature Box

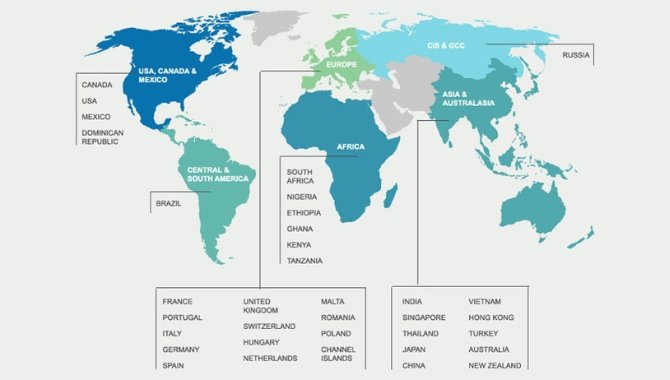

Worldwide Performance

Over 100 power utilities throughout the world used our XLPE Insulated Power Cable and They are all satisfied with our cable quality and after-sale technical support.

Custom Design of your XLPE Insulated Power Cables

No matter where your project is located in the coldest area or the hottest desert, our dedicated expert engineers can provide you a custom design for an XLPE Insulated power cable to fit your unique requirement.

Package Supply of Cables & its Accessories

Except for a medium or a high voltage XLPE insulated power cable, we can also provide you cable accessories as well, a seamless connection for your electrical system will be assured.

Cable Installation & On-site Technical Support

We are dedicated to offering the best quality technical support. Our Technical Consultants are amongst the most experienced people in the field and are available to come to your jobsite to address any technical queries you may have.

What is XLPE and its Advantages

It is known to all, XLPE is an abbreviation for Cross Linked Polyethylene, which is a polymer material that transforms polyethylene molecules from a linear structure to a network structure through chemical or physical transformation, and significantly improves its heat resistance, mechanical properties, and electrical properties etc.

Advantages of an XLPE material

- Super heat resistance

For an XLPE insulated power cable, its normal operation temperature is at 90 ℃, and it can withstand a high temperature of 250 ℃ at a short time when there is short circuit occurred in a power transmission & distribution system. Compared to conventional PVC materials, XLPE has a much higher heat resistance and is more suitable for high-temperature applications.

- His high electrical performance

Drawing on his good performance of high dielectric strength, low dielectric loss, and good insulation , It is able to prevent current leakage, thus to assure there is no bad effect to its associated electrical equipment. It has a high breakdown voltage and can withstand power transmission under high voltage conditions.

- Good mechanical performance

Based on its high tensile strength, impact and abrasion resistance, It can used in all hazardous conditions. Its elongation at break exceeds 300%, and its tensile strength is about 15 to 25 MPa.

- Strong chemical stability

XLPE is free to acids and some other chemicals, making it possible working smoothly for harsh environments.meanwhile, it is not easy to cause fire, thus improve its fire resistance and ensure a higher safety.

- Long service life

XLPE material has excellent anti-aging performance, and its service life can reach 40 years. Its cross-linked structure suppresses the spread of electrical branches, further extending the service life of the cable.

- Friendly to environment

XLPE has a relatively small impact on the environment during production and daily operation; it is a friendly material to environmental protections.

Main Features of our XLPE Insulated Cables

Excellent Electrical and Physical Properties; A larger current carrying capability.

Easy Installation; Free from height limitation & Maintainance;

Related Product

What types of XLPE Insulated Power Cable

According to its voltage level, it would be low, medium, high voltage and even extra high voltage power cables.

Manufacturing process of an XLPE insulated power cables

It may includes the following important steps:

- Procurement for all necessary raw materials

This may include aluminum or copper conductors; XLPE, in our factories, we always choose some well-known brands in this industry, normally it is DUPONT, a U.S based company and/or Borealis, with the considerations of their high quality and stability.

- Manufacturing the conductors

An annealing process for the conductors is quite important in this step, which has a direct impact to the flexibility and conductivity for the whole power cables.

- Extrusion and cross-linking of insulation layer

Triple-extrusion technology is used in this process: conductor shielding layer, insulation layer, and insulation shielding layer can be came out at same time through a triple-extrusion equipment, to guarantee its uniform electric field distribution and reduce partial discharge.

Normally, this step is able to reflect the manufacturing capabilities and its level for a company or a cable factory.

- Cooling and shaping of the insulation layer

The extruded insulation layer is shaped by a cooling device to ensure its dimensional accuracy and shape stability.

- Shielding layer and outer sheath

Shielding layer: Adding a metal shielding layer, commonly an aluminum or a copper tape applied outside the insulation layer to limit the interference of electric and magnetic fields.

- outer sheath: mostly use polyvinyl chloride (PVC) or polyethylene (PE) ,drawing on their excellent abrasion performance , thus to provide physical protection and prevent damage to the cable from the external attacks.

- Routine testings for the cables

After finish all production process, a strict routine testing is required for the cables, including electrical performance testing, mechanical performance testing, and environmental resistance testing, to ensure the cables fully comply with all related standard and design values.

- Packaging and Storage

After the routine testing worked, the cables are approved to be Qualified and move into the next step for packing the cable reels and stor in a dry and ventilated warehouse to prevent moisture and damage.

- Shipping & delivery

Book the containers to load the reels into the containers; in this process, fixing the reels in a container is also very important; enough triple-angle chops need to be used to fix the reels to avoid the damage during the whole shipping process; for some power cables in a big size of the conductor and in a long continuous length, we have to use some flat-bed trucks or some top-open containers.